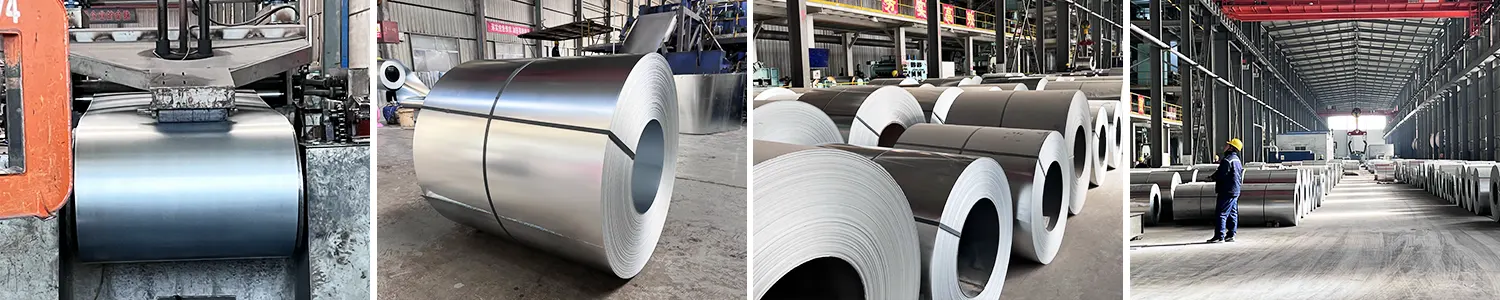

Cold hard rolled plate

Cold rolled plate is ordinary carbon structural steel cold rolled plate, is made of ordinary carbon junction of water steel hot rolled steel strip, after further cold rolling of the steel plate. Shandong Huixin under the Shandong Tang Rong New Materials Co., Ltd. has a six-roll reversible cold rolling mill set of seven (sets), by the Xi'an Prudential Metallurgical general contracting, Baowu Iron and Steel Changzhou Baoling Heavy Industry processing and manufacturing, the design capacity of 1.68 million tons per year.

1, the appearance of the general cold hard coil plate a little hair slightly black.

2, surface quality, structure, dimensional accuracy of cold rolled sheet to be better than cold hard coil.

3, performance, due to the hot rolled coil through the cold rolling process directly to get the cold hard coil in the cold rolling process hardening, resulting in increased yield strength, and residual part of the internal stress, the external performance of the more "hard" so called cold hard coil.

Production process

Cold rolled sheet is a product made from hot rolled coil as raw material and rolled below recrystallization temperature at room temperature. Cold rolling is rolling under the recrystallization temperature, but is generally understood as rolling using room temperature rolling materials. It is mostly used in automobile manufacturing, electrical products, etc.

The production process is not heated, so there is no hot-rolled often occurring pitting and iron oxide and other defects, good surface quality, high finish. Moreover, the dimensional accuracy of the cold rolled products is high, and the performance and organization of the products can meet some special requirements, such as electromagnetic properties, deep drawing properties.

Applications

Cold rolled sheet has a wide range of applications, mainly used in automotive, printing iron barrels, construction, building materials, bicycles and other industries, but also the production of organic coated steel plate ideal choice.

MORE NEWS

A214 Carbon Steel Round Bar: Key Insights for the Metallurgy and Energy Industry

A214 carbon steel round bars are a versatile choice within the metallurgy and energy sectors. Known for their strength and durability, these bars are commonly utilized in various applications, including structural components, manufacturing machinery parts, and tools. Understanding the characteristics of A214 carbon steel is vital for optimizing production processes and selecting the right material

2025-12-15

ST12 Cold Rolled Steel Sheets vs. Other Steel Types: Essential Insights for Informed Decision-Making

ST12 Cold Rolled Steel Sheets vs. Other Steel Types: Essential Insights for Informed Decision-Making Table of Contents 1. Introduction to Cold Rolled Steel 2. What is ST12 Cold Rolled Steel? 3. Benefits of ST12 Cold Rolled Steel Sheets 4. A Comparative Analysis of ST12 and Other Steel Types 4.1 ST12 vs. Mild Steel 4.2 ST12 vs. High-Strength Steel 4.3 ST12 vs

2025-12-08

Understanding NM400 Carbon Steel Plate: A Key Material in Construction and Decoration

NM400 carbon steel plate is a high-strength material known for its exceptional hardness and wear resistance, making it a popular choice in various construction and decoration applications. With its tensile strength and improved resistance to abrasion, NM400 is often utilized in environments where durability is essential, such as mining, construction, and heavy machinery. One of the defining featur

2025-12-01

Top Industries Benefiting from Hastelloy C-276 Stainless Steel: Unveiling the Versatile Applications

Top Industries Benefiting from Hastelloy C-276 Stainless Steel Introduction to Hastelloy C-276 Stainless Steel Hastelloy C-276 stainless steel is a **high-performance alloy** that offers exceptional resistance to corrosion and high temperatures. Developed by Haynes International, this nickel-molybdenum-chromium alloy is renowned for its unique properties, making it a preferred choice in various de

2025-11-24

Understanding DC01 Carbon Steel Coil: Properties and Applications

DC01 carbon steel coil is a widely utilized material in various industries due to its unique properties and versatility. As a type of cold-rolled steel, DC01 is known for its excellent surface finish and dimensional accuracy, making it suitable for precision applications. It boasts a low carbon content, typically around 0.06% to 0.12%, which contributes to its good formability and weldability. Thi

2025-11-17

Understanding the Properties of SPHC Carbon Steel Coils for Builders: The Essential Guide

Understanding the Properties of SPHC Carbon Steel Coils for Builders Table of Contents 1. Introduction to SPHC Carbon Steel Coils 2. What is SPHC Steel? 3. Key Properties of SPHC Carbon Steel Coils 3.1 Mechanical Properties 3.2 Chemical Properties 3.3 Physical Properties 4. Applications of SPHC Carbon Steel Coils 5. Advantages of Using SPHC Carbon Steel Coils

2025-11-10