Fluorocarbon plate

Categorization:

Fluorocarbon plate

Keywords:

Fluorocarbon plate

Silver Sea New Material

DETALLES

Fluorocarbon panel is the use of fluorocarbon process of fastening board. The so-called fluorocarbon process refers to the coating process with fluorocarbon resin as the main film-forming material; also known as fluorocarbon paint, fluorine paint, fluorine resin paint, etc. Among the various coating processes, fluorine resin coating has particularly superior properties due to the introduction of fluorine element with high electronegativity and strong carbon-fluorine bonding: weather resistance, heat resistance, low temperature resistance, chemical resistance, and unique non-stick and low friction properties.

Fluorocarbon board advantages:

(1) excellent anti-corrosion properties - thanks to excellent chemical inertia, paint film resistance to acids, alkalis, salts and other chemicals and a variety of chemical solvents, to provide a protective barrier for the substrate; the paint film tough - high surface hardness, impact resistance, resistance to flexing, good wear resistance, showing excellent physical and mechanical properties.

(2) maintenance-free, self-cleaning - fluorocarbon coating has a very low surface energy, surface dust can be self-cleaning through rain, excellent hydrophobicity (maximum water absorption rate of less than 5%) and repellent to oil, a very small coefficient of friction (0.15-0.17), will not stick to the dust and dirt, good antifouling properties.

(3) Long weather resistance - coating contains a large number of F - C bond, determines its strong stability, not chalking, do not fade, fluorocarbon plate surface coating curing furnace temperature is generally between 180 ℃ ~ 250 ℃, curing time of 15-25 minutes, so the plate has a strong weather resistance and ultraviolet resistance, color and luster to maintain a long service life The service life is more than 20-30 years. Resistance to artificial climate aging is 1.5 times that of other fluorocarbon coated panels.

(5) Green environmental protection - the production process does not use any solvents, volatile organic compounds (radon) <200Bq/m3, no ammonia, no stupidity, no formaldehyde, the radioactivity reaches the standard of Class A decoration materials, the scope of use is not restricted.

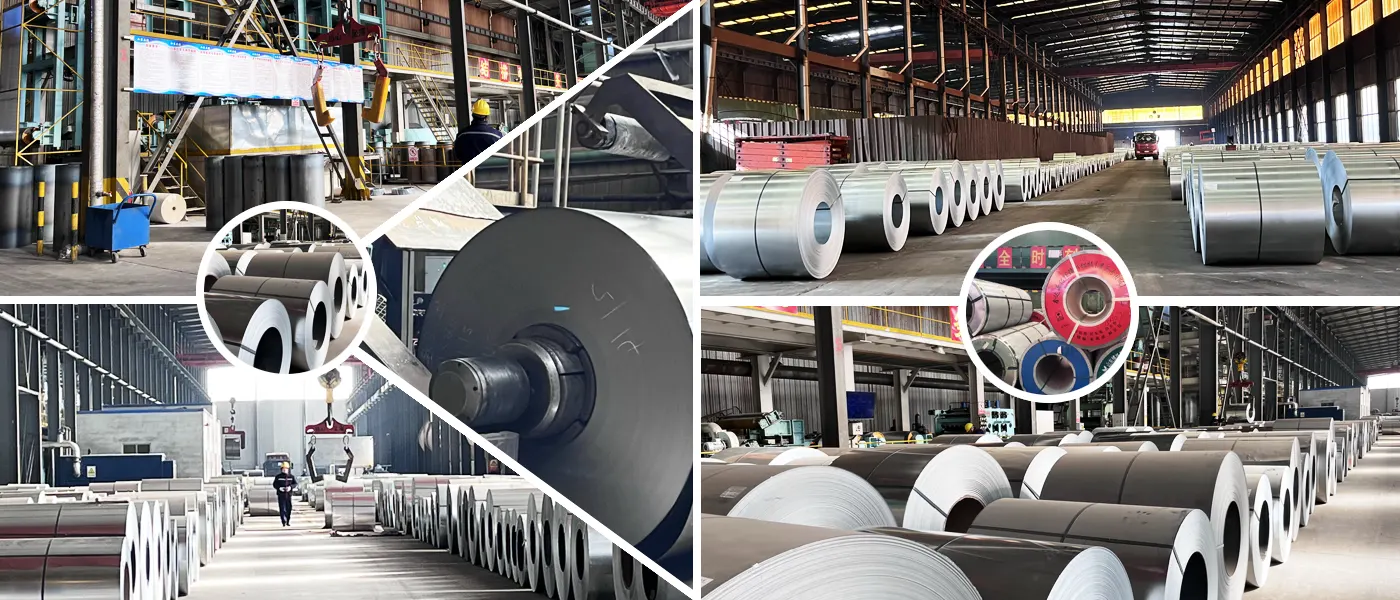

Warehouse Storage

Our company is committed to providing a range of high-quality, innovative and cost-effective steel products that are widely used in various industries. We strive to create value for customers and meet their various needs. The company has the operating advantages of complete specifications, low prices, and fast delivery. With its trustworthy and quality-focused service concept, the company has won the trust and praise of customers at home and abroad.

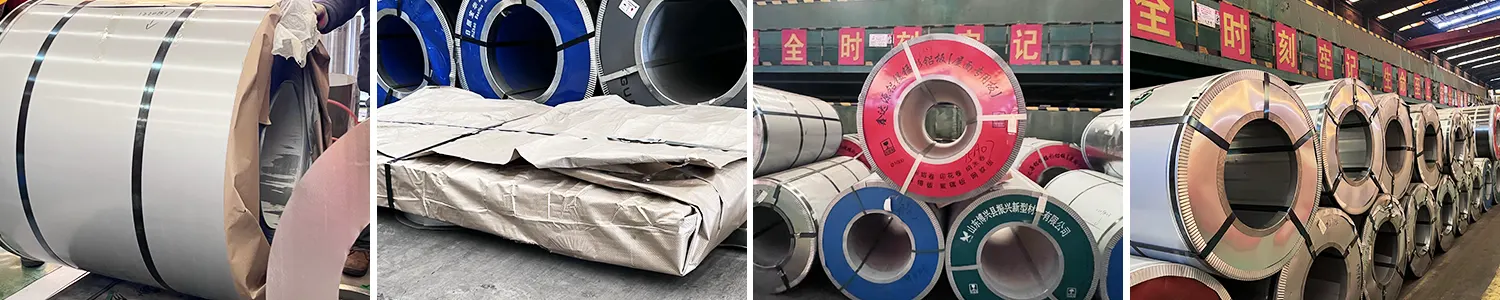

Packing and shipping

Our products have been exported to Southeast Asia, the Middle East, South America, Europe, Oceania and other countries and regions, enjoying a good reputation. The product packaging has an inner layer of waterproof paper and an outer layer, iron packaging, and wooden pallets that are fumigated and fixed. It can effectively protect products from corrosion during ocean transportation. Domestic and foreign customers are welcome to call us for consultation and ordering.

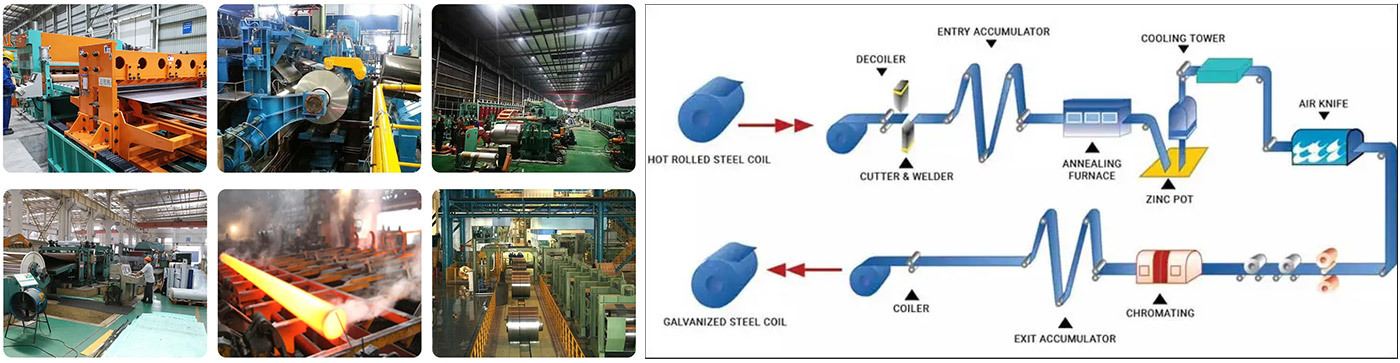

Technology

Application field

The main supply areas are: aerospace, chemical industry, shipbuilding, nuclear energy, trains, environmental protection, precision processing, auto parts, machinery, electronic products, molds, medical equipment, construction, decoration, etc.

Leave A Message